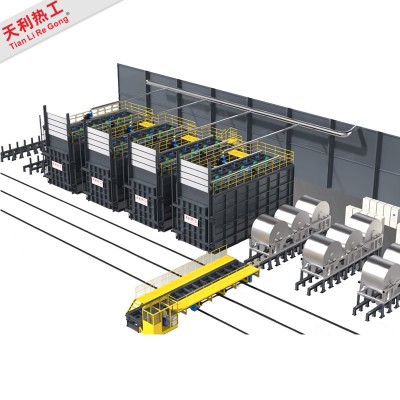

结构形式

本台车式加热炉主要由炉体(炉子骨架和内衬)、台车及台车驱动机构、炉门及炉门升降机构、炉压控制系统、密封装置、燃烧及自动控制系统、管路及管路自动控制系统、供风系统、排烟及余热回收系统、温度控制系统、电气控制系统等组成

应用范围

本蓄热式燃气台车炉主要温度不高于1250℃的锻件毛坯加热,又可进行淬火、正火、回火等热处理工艺。

结构特点

本蓄热式燃气台车炉采用天然气作燃料,与燃烧系统、温控系统及程序控制系统配套使用,可自动控制燃烧工况、记录工作温度及加热炉各种动作的自动化(含手动)操作。

技术规格

No.序号 | Item内容 | Specifications规格 | Unit单位 | Remarks备注 |

Workpiece information 工件信息

| Application: heat treatment for steel and alloy billets 合金钢胚料 | |||

1 | Working zone size of furnace炉膛有效尺寸 | 2500 x 1000 x 800 mm | mm | L*W*H |

2 | Heat treatment type 热处理类型 | Quenching furnace 淬火 | ||

3 | Loading weight of trolley装载量 | 5T (exclude the shim plate不含垫铁) | ton吨 | |

4 | External temperature of furnace 炉外壁温升 | ≤45℃+room temperature室温 | ℃ | lateral wall 侧墙 |

≤55℃+room temperature室温 | Roof 顶部 | |||

5 | Temperature increasing speed 升温速度 | 0~150℃/h (adjustable可调的) | ||

6 | Adjustable cooling rate 冷却速度 | 10-100 ℃/h (adjustable可调的) | ||

7 | Working temperature最高工作温度 | ≤1260(≦1h/天) | ℃ | |

8 | Temperature control precision 控温精度 | ≦3℃ | ℃ | Temperature control system |

Instrument control system | ||||

9 | Furnace uniformity during holding period 保温阶段炉温均匀性) | ±10 ℃ | ℃ | |

10 | Temperature control zones (温控区) | 2 | zone | |

11 | Temperature control method(控温方式) | Intelligent instrument control+ PLC control with manual control 智能控制+PLC+触摸屏+手动控制 | Touch panel + PLC | |

12 | Thermocouple(热电偶) | N 型/4 支 | ||

13 | Burner(烧嘴) | 高速烧嘴 型号: SCEM 80LN power:150kw | 品牌:广州施能 | |

14 | Heating method加热方式 | 天然气(~8500Kcal/m3) | ||

15 | Combustion method燃烧方式 | 大小火 | ||

16 | Fuel& Calorific value of fuel 热值 | 8500Kcal/m3 | KJ/m3 | |

17 | Max gas consumption in Chamber 炉膛最大燃气消耗量 | 60 | Nm3/h | |

18 | Max air consumption in Chamber 炉膛最大空气消耗量 | 660 | ||

19 | Max waste gas exhausting quantity 废气量 | 750 | ||

20 | Gas pressure before the burner | 5~8 | KPa | |

21 | Air pressure before the burner 烧嘴前空气压力 | 5~8 | KPa | |

22 | Total gas pressure 总管压力 | 50-100 | kpa | |

23 | Heating exchanger | 1 sets of plug-in tubular heat exchanger 1台插入式换热器 | ||

24 | Combustion air temperature 预热空气温度 | 50℃-250℃ | ||

25 | Waste heat recovery 预热利用 | According to GB3486-93 | ||

26 | Furnace door opening method 炉门开启方式 | Electric hoist 电动葫芦 | ||

27 | Furnace door sealing method 炉门密封方式 | Self-press by its heavy 自重轨迹压紧 | ||

28 | Trolley driving speed 台车传动方式 | 6-8 | m/min | |

豫公网安备 41072602000418号

豫公网安备 41072602000418号